Resistive evaporation coating equipment

|

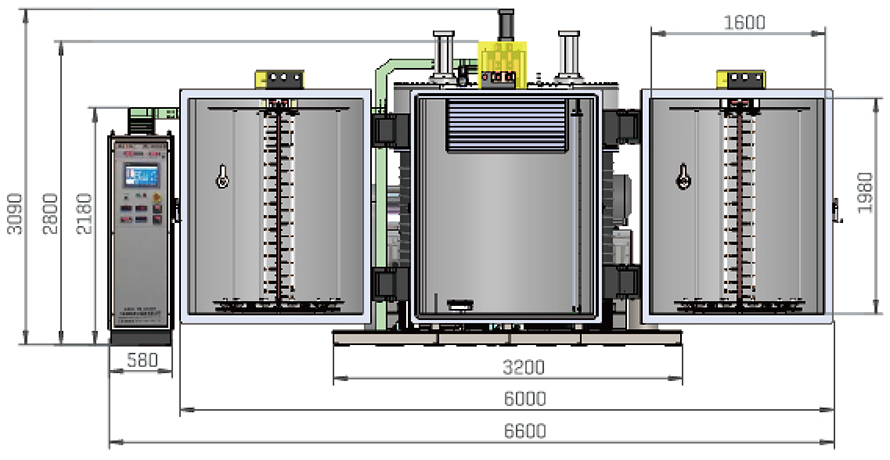

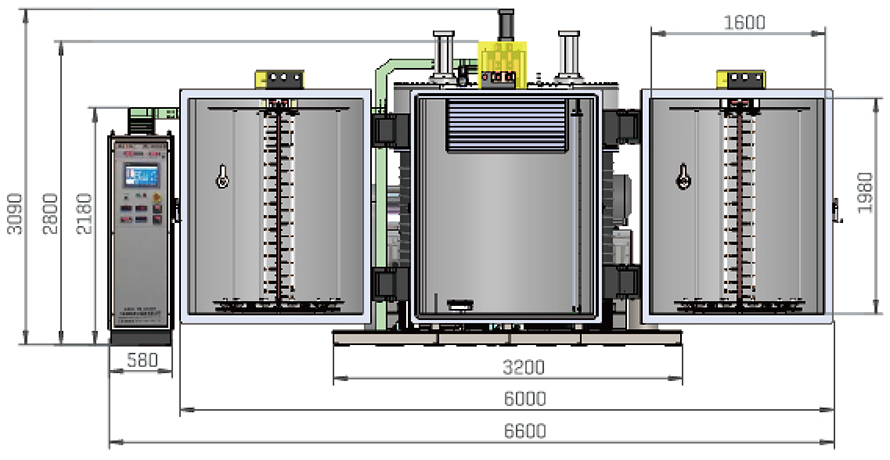

Front view of WLT vacuum VLT-1600B dual-unit coating machine |

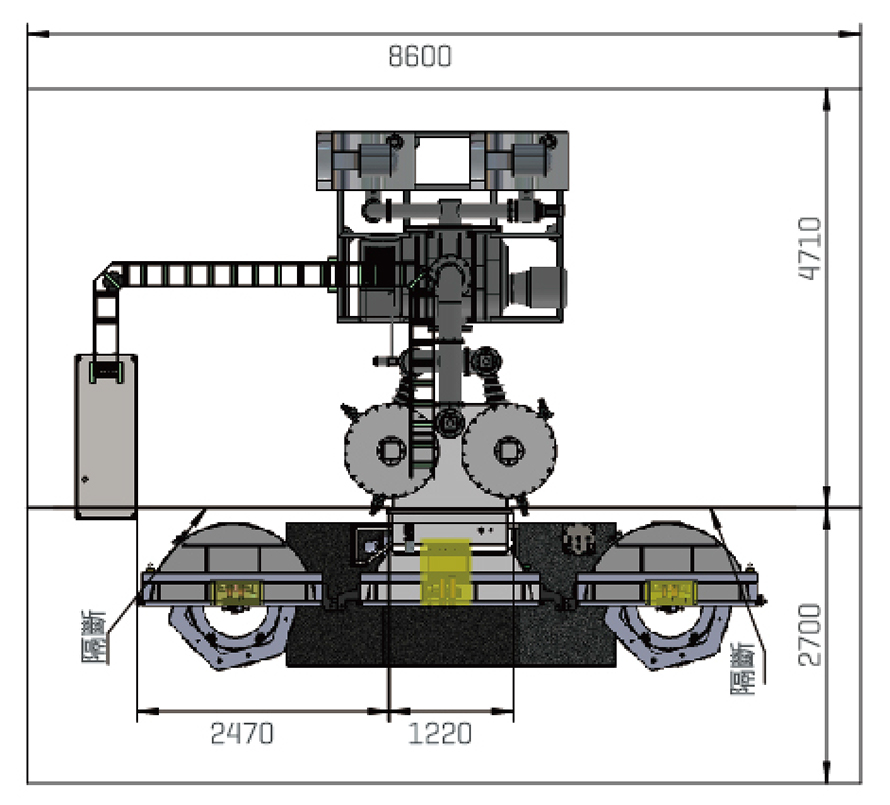

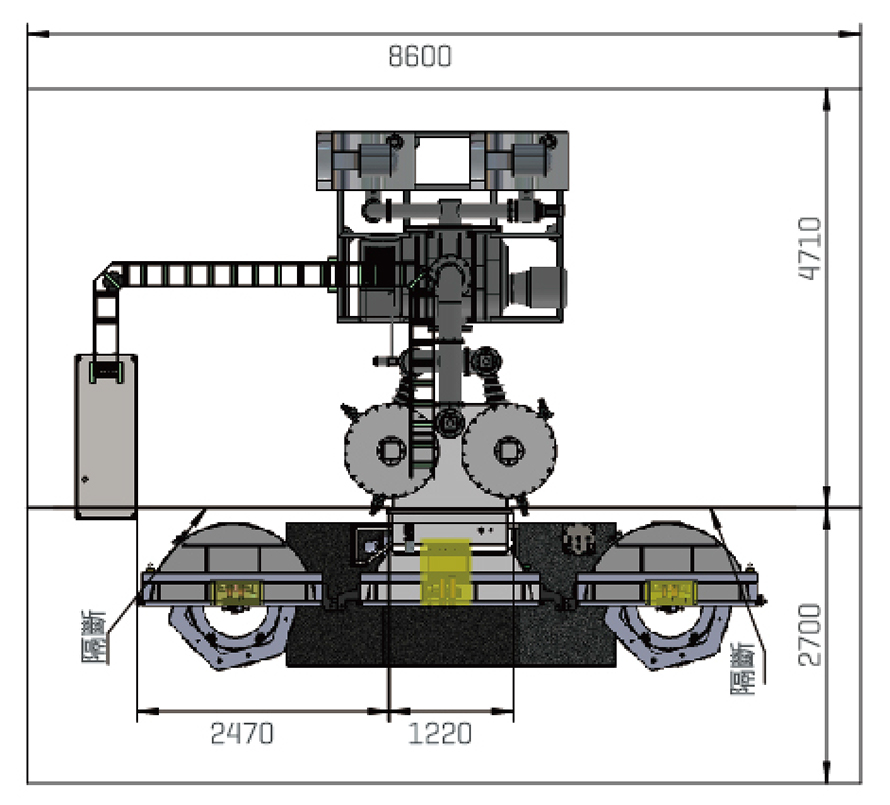

Top view of VLT vacuum VLT-1600B dual-unit coating machine |

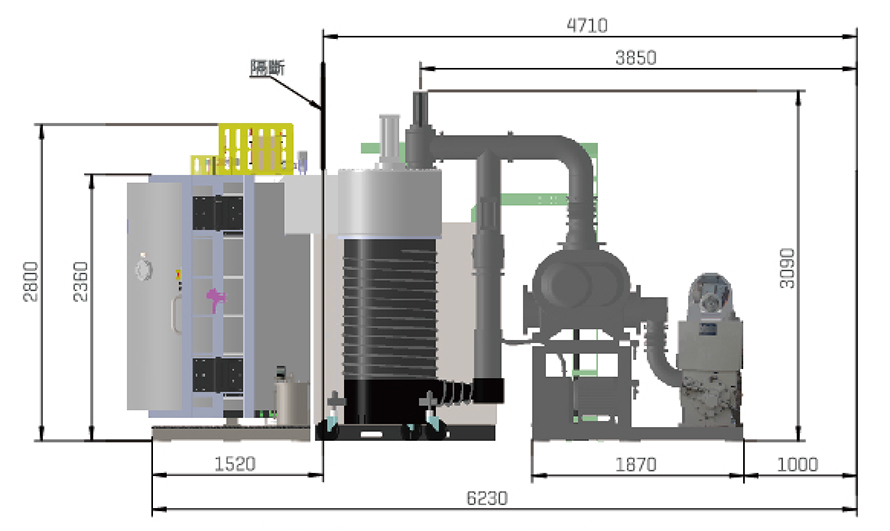

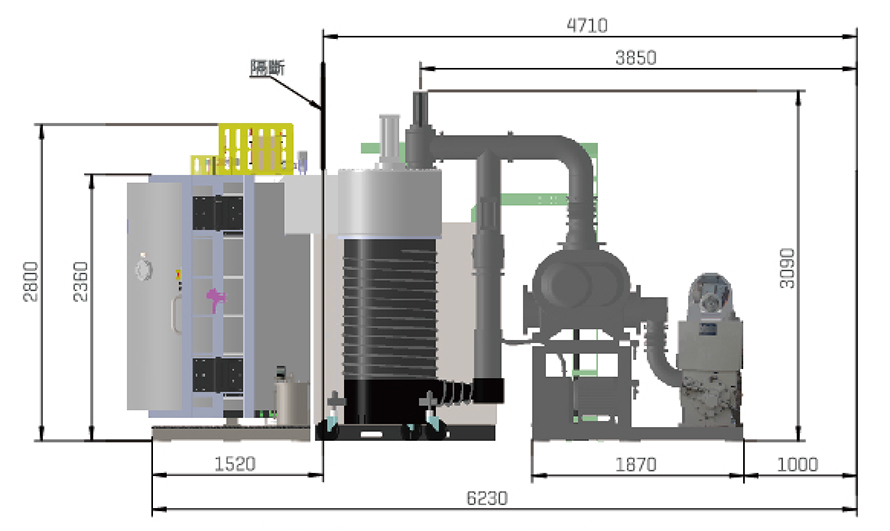

Side view of VLT vacuum VLT-1600B dual-unit coating machine |

Technical parameter

|

Device model |

VLT-1000B |

VLT-1200B |

VLT-1400B |

VLT-1500B |

VLT-1600B |

VLT-1800B |

VLT-2000B |

|

Size |

1000×1500 |

1200×1650 |

1400×1800 |

1500×1850 |

1600×1950 |

1800×1950 |

2000×2100 |

Power supply type: resistance heating tungsten filament evaporation transformer power supply, high-voltage ion bombardment power supply, thyristor power supply

Structure: vertical double door, air pumping system

Vacuum system: slide valve pump + roots pump + diffusion pump maintenance pump (or optional: cryogenic pump, cryogenic system)

Ultimate vacuum: 6×10-4pa (no load, clean room)

Pumping room: no-load air pumping to 5×10- 2pa less than or equal to 6 minutes

Workpiece rotation: single axis/6 axis/8 axis revolution/inverter stepless speed regulation

Control mode: manual + semi-automatic + fully automatic integration / touch screen + PLC

Remarks: The size of the vacuum chamber can be customized according to customer's product and special process requirements

Equipment characteristics

Production period: -900sec (15 minutes)/1 period shorter than that of similar equipment

Coating method: heating wire evaporation coating method

Coating quality: Each door has 6`8 sets of fixtures, and the coating thickness is uniform at the same time for autobiography and revolution. It is suitable for mass production of economical car lamps. Dehumidification capacity: The vacuum chamber is equipped with an ultra-low temperature freezing system below minus 140 degrees to fully absorb moisture. Vacuum reach speed

Operating cost: The volume of the vacuum chamber is relatively large, the number of coatings is large each time, and the operating cost of a single piece is low

Number of fixtures: According to the size of the product, the fixture can be changed to 6 axis or 8 axis at will, without any installation and adjustment when changing

Floor area: double-door structure, relatively smaller installation area and operation area than similar equipment

Operation method: The man-machine interface can be set and monitored intuitively, and the person who has no management password can not change it

After-sales service: There is an after-sales service center and parts warehouse, which can quickly deal with problems in use

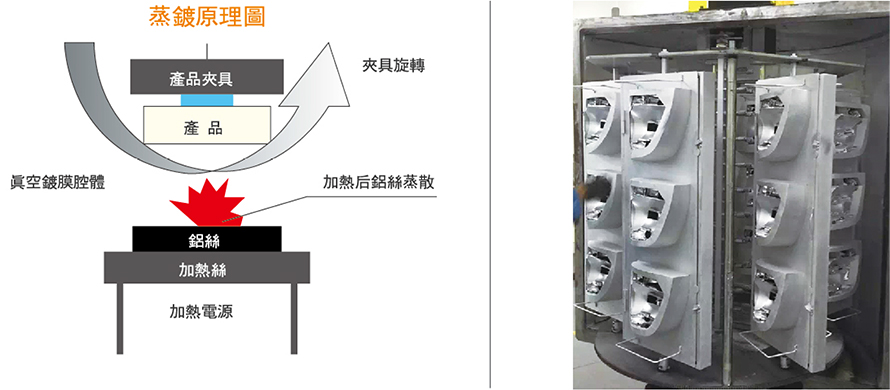

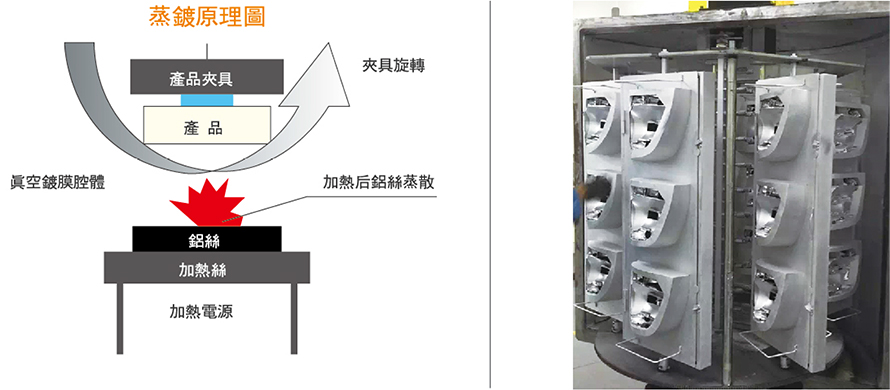

Equipment principle diagram

Left: Apply a certain voltage to the heating wire in a suitable vacuum environment to evaporate the aluminum wire placed on the heating wire to the surface of the rotating product to achieve the purpose of aluminum plating.

Right: According to the size of the product, change the 6-axis fixture at will, (when the product size is relatively large, each vacuum chamber is equipped with six fixtures) or 8-axis (when the product size is relatively small, each vacuum chamber is equipped with 8 fixtures), it is not necessary for replacement Any installation and adjustment.

PERSONMr. Cheng

PERSONMr. Cheng TEL0510-88769360

TEL0510-88769360  FAX0510-88769196

FAX0510-88769196 WEBwww.jsvltvac.com

WEBwww.jsvltvac.com E-MAILCL@jsvltvac.com

E-MAILCL@jsvltvac.com ADDNo. 11, Nongke Team Road,

ADDNo. 11, Nongke Team Road,